Pros and Cons of different gas flow measurement technologies available in the market will help process instrumentation engineers to effectively choose best flow metering technology for defined application which results in optimum results w.r.t cost versus performance ratio.

Process instrumentation engineer’s task is to identify which of the Mass flow meter technology will be best suitable technology.

Below are some important factors to be considered & evaluated with comparing technologies for optimum selections:

– Pipe sizes

– Process conditions such as flow rate, pressure, temperature, density, viscosity, dirt & moisture, etc.

– Installation conditions such as horizontal, vertical, or inclined & available straight lengths, time & efforts, etc.

– Accuracy & repeatability needed

– Process turn down ratio needed

– Budgeted price

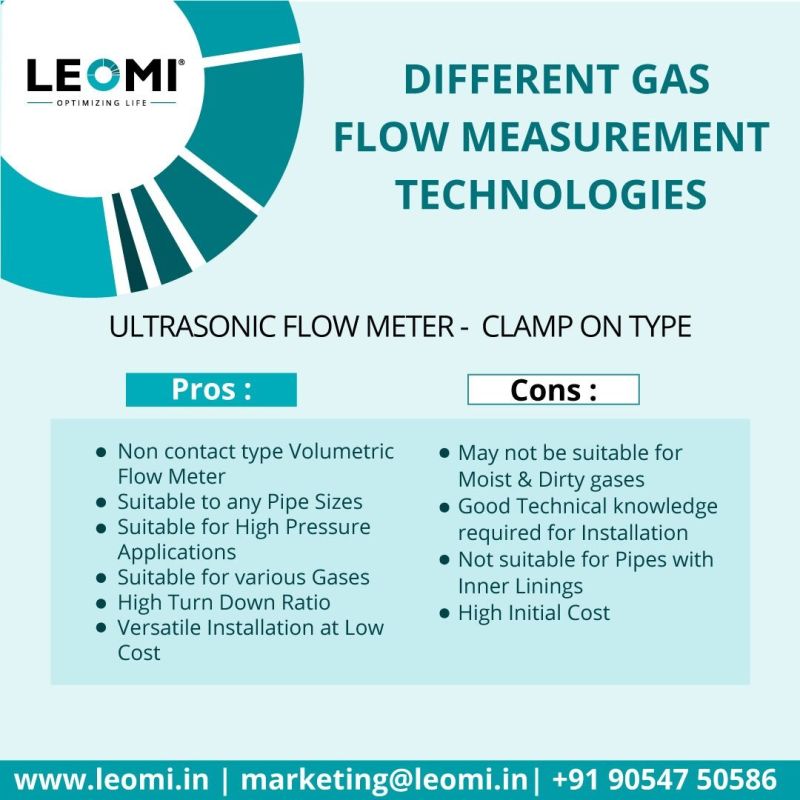

Here are the Pros and Cons of Ultrasonic Flow Meter- Clamp-on Type

Pros :

1. Non-contact type volumetric flow meter

2. Suitable 5o any pipe sizes

3. Suitable to high pressure

4. High turn down ratio

Cons :

1. May be not Suitable for moist and dirty gases

2. High initial cost

3. Most Suitable for pipes with inner lining