Problem

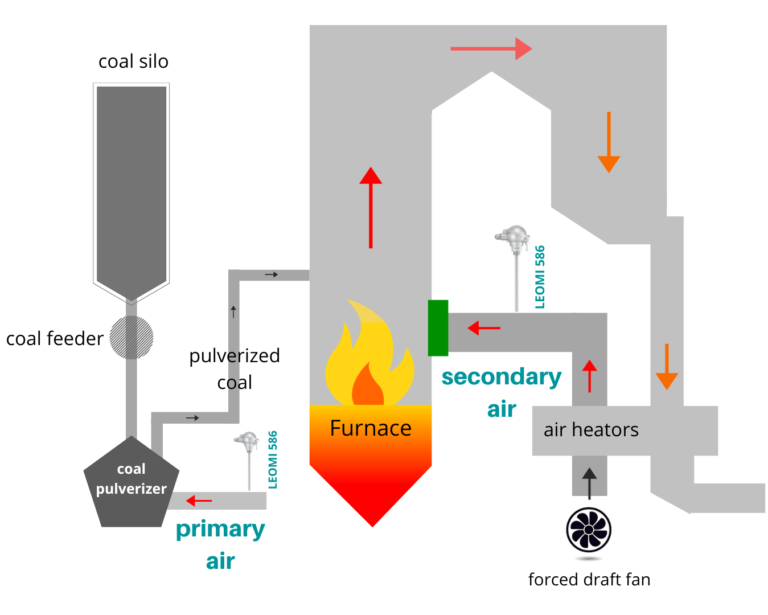

Captive Thermal Power Plant produces heat energy and electricity. Efficient operation of today’s thermal power plant depends largely upon accurate and repeatable measurement of primary and secondary air flow to coal mills. Combustion air plays an important role to maintain air-fuel stoichiometric ratio for optimal combustion of fuel in boilers.

- Primary air has high volume at very low static pressure in large ducts.

- Low velocity & high temperature from 150⁰C to 400⁰C from APH (Air preheater)

- Differential pressure flowmeters (Aerofoil or Pitot-tube) don’t work at low flow rates.

- Existing DP flowmeter has high pressure drop & low accuracy upto (3%-4% FSD).

Solution

Leomi – 586 Insertion Thermal Mass flowmeter

- High turndown down ratio of 100:1 against 4:1 of existing installation.

- No pressure drop, Works well even in high temperature & low velocity

- High accuracy upto (±2%) against DP flowmeter (±4% FSD)

- Doesn’t require shutdown for installation

- No clogging due to air laden dust

- No maintenance than the existing flow meter used.

Application

Combustion Air flow measurement in Thermal Power Plant

Customer

Reputed 200MW Captive Thermal Power Plant in Cement Plant complex, India.

Product

LEOMI- 586, Insertion Thermal Mass Flowmeter

Why Leomi?

- An ISO 9001:2015 company, Startup India recognized

- German technical collaboration Engineered in India

- India’s First In-house fully automatic wind tunnel calibration system

- Product quality proven for more than 20 years installed worldwide.

Installation Facts

Leomi 586 is installed at the ID Blower Fan outlet for Primary air flow into Boiler with rectangular duct of 1400mm X 1200mm and flow rates upto 1,20,000 Nm3/hr. It has been working for the past 10 years without any maintenance.

Download the Complete Case Study