Cement Industry is one of the crucial core sectors for the development of construction and infrastructure with currently approx. 4.4 billion Tonnes of cement was produced in the world in the year 2021. The largest cement producer is China with more than 55% capacity and thereafter India accounts for the second largest product with around 7% of capacity.

After the COVID-19 pandemic, there was a sudden rise in demand from rural and urban infrastructural developments across the world and mostly in undeveloped countries. Initiatives such as the Smart City project by India will see a long-term demand for cement products which will see huge technological upgradation of existing cement plants for cost and energy optimization.

The cement industry is one of the most intensive energy consumers in the industrial sectors. Energy consumption represents 40% to 60% of production costs. Additionally, the cement industry contributes around 5% to 8% of all man-made CO2 emissions. Due to increasing demand efficiency and optimization will be the key criteria for today’s cement plant operators which will largely depend on the accurate and repeatable measurement of various process parameters such as Temperature, Pressure, Flow Rate & Level, etc.

In the cement industry generally pressures, temperatures are used for calculating process gas flows in correlation with Fan/Blowers’s speed & power consumption, however, this is an assumption that generates high uncertainties against the actual gas flow rate and energy consumption of prime mover such as Fan/Blowers.

There is an urgent need for optimum control of Air and process gas flow monitoring for improving the overall quality of cement, efficiency, and cost optimization for many process requirements as below:

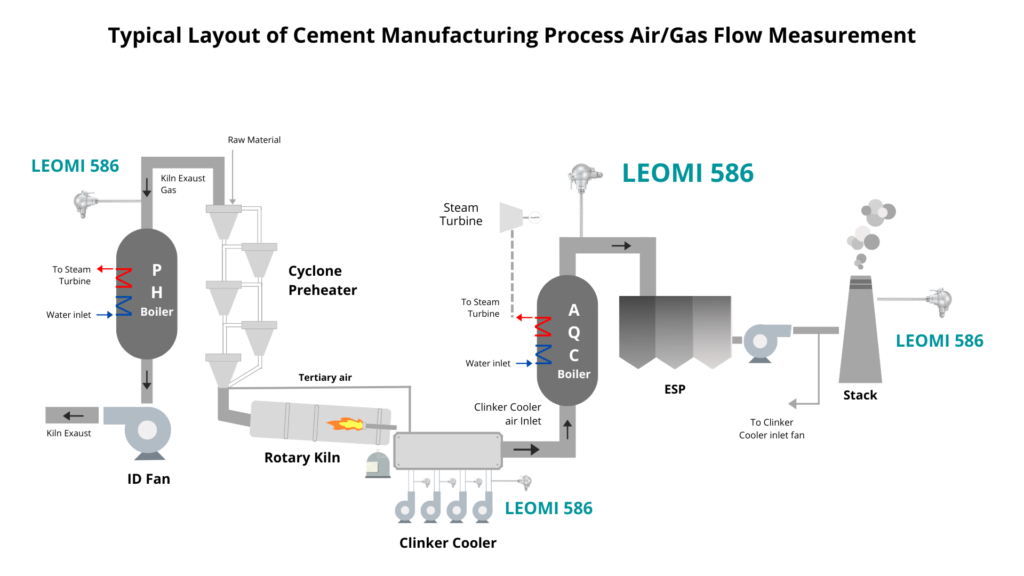

1. PREHEATER PROCESS EXHAUST GAS FLOW RATE MEASUREMENT

Cyclone Preheaters are used before rotary kilns of cement production plants to heat the raw mix and drive off carbon dioxide and water before it is fed into the kiln. The quality of the preheater in a cement plant directly affects the stability of calcining temperature and cement clinker quality in the kiln. Measuring the exhaust gas flow rate in the downcomer can help in fine control of the ID Fan downstream for optimum control of the O2 content of the kiln off gas.

Exhaust gas flow measurement generally is challenging due to the large diameter of the duct, high dust concentration, and high temperatures around 350⁰C-400⁰C. Generally, velocity is measured temporarily by Pitot tube with high uncertainties for cross-checking which doesn’t help in the efficient control of the process.

2. CLINKER COOLER AIR FAN FLOW RATE MEASUREMENT

The clinker cooler is a key device in the clinker production line which helps in quenching and transports the hot clinkers discharged from the rotary kiln and supplies hot air for the rotary kiln and preheater system. As the first equipment where high-temperature clinker releases heat, it plays an indispensable role in reducing coal and power consumption, increasing secondary and tertiary air temperature, and improving heat recovery rate.

A good clinker cooler can help cement plants reduce energy consumption from two aspects: one is to improve the cooling efficiency and reduce the power consumption of the clinker cooler itself; the other is to reduce the coal consumption of rotary kiln and preheating systems by improving the heat recovery rate. Clinker cooler grate air fan efficient control is vital in achieving cooling efficiency and energy saving with a higher cooling rate concerning feed rate adjustment. Continuous cooling air flow rate measurement plays an important role in optimizing the operation of a clinker cooler.

Measurement of a cooler air fan is a challenging task due to the high concentration of clinker dust with a high abrasion rate where flow sensors need to be robust and immune to high abrasion resistance. Currently, this application has a limited flow solution and less life expectancy about 1-6 months.

3. AQC BOILER & PHP PROCESS GAS OUTLET FLOW MEASUREMENT

Modern cement plants are equipped with Waste heat recovery (WHR) power plants installed in cement plants, using the heat generated through rotary kiln preheater (PH) and AQC exhaust hot gases for power generation. Waste heat recovery systems (WHRS) wherein hot waste gas heat from rotary kiln preheater & clinker cooler is fed to Preheater (PH) Boiler & After quenching chambers (AQC) boilers to recover heat energy for running boilers for electricity/power generation with the help of steam turbines. Typically, the 20 to 30 percent power requirement of the cement plant can be fulfilled using this waste heat for power generation applications, which is a substantial savings/reduction in the overall cost of production.

Efficient control of PH & AQC Boiler needs an accurate and reliable inlet or outlet gas flow rate which demands a flow measurement device suitable for high temperature and abrasion resistance design.

4. PRIMARY AIR FAN FLOW MEASUREMENT IN POWER GENERATION BOILERS

Cement Plant is installed with Captive Coal Power Plant for fulfilling additional needs of electricity apart from AQC & PH Waste heat recovery Boilers. Primary airflow into the boiler is important to monitor for maintaining optimum stoichiometric air-to-fuel ratio for achieving efficient combustion efficiency. A reliable and accurate primary air flow measurement is needed which has low-pressure drop and works well at low static pressure and low maintenance.

5. PROCESS & FLUE GAS FLOW MEASUREMENT IN EXHAUST STACK

Exhaust process flue gas from clinker cooler and boiler needs to be monitored by the pollution control authority for keeping control on emission guidelines is a must. This needs accurate and reliable flow measurement solutions which will help in achieving high thermal efficiency and improve ESP performance & help to regulate harmful pollutants emission controls & provides useful information on optimizing mass balance.

6. COMPRESSED AIR MEASUREMENT FOR UTILITY CONTROL AND CONSERVATION

Compressed air is used as a utility in cement plants for the efficient operation of pneumatic equipment used in packing plants and other miscellaneous use needs to be monitored as it is invisible energy as for producing 4 scfm compressed air one horsepower (HP) electrical energy is consumed.

An accurate air & gas flow measurement in cement production helps in

- Reducing Blower (ID/FD Fan) power consumption i.e., energy saving

- Controlling the accurate and repeatable operation of kiln & improving clinker production quality

- Improves energy efficiency of Clinker cooler fan & energy conservation

Major Challenges in existing flow measurement solutions for the above applications

- High-pressure drop means energy loss

- Lower turn-down ratio implies limited operational range and leakage insensitive.

- Lower accuracy & measurement resolution implies limited efficiency & performance analysis

- Clogging and high wear factor

- High cost of installation & needs frequent maintenance.

Overcoming above challenges by advance proven calorimetric (heat dissipation) technology:

Nowadays Insertion Thermal Mass (Heat dissipation) Flow meter technology is gaining technical ground for solving above limitations of existing conventional pitot tube or annbar differential pressure-based flow measurement.

Insertion Thermal Mass Flowmeter

Working Principle

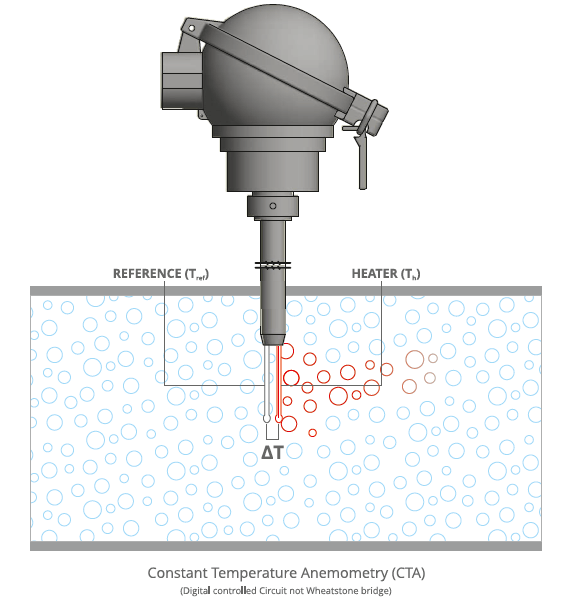

Thermal mass (calorimetric) flow meters work on the physical principle of thermal dispersion from a heated element to the ambient medium (e.g., air or gases). This is affected by the velocity, density (temperature and pressure) and by the characteristic of the medium. The amount of needed energy is a function of the temperature difference ∆T and the mass flow.

Gas flowing through two RTD Pt-100 one reference (Tref) and another Heater (Th). The temperature difference (over temperature) ∆t between the reference sensor (medium temperature) and the heater sensor is controlled constant. As per King’s Law, higher the mass flow rate, higher the cooling effect of the heater sensor, thus higher the power required to maintain the differential temperature constant. Therefore, the heater power is proportional to the gas mass flow rate.

Advantages of Insertion Thermal Mass Flow metering technology against conventional flow metering

- Pipe sizes suitable 15mm to 10 metres

- Easy Installation, orientation & rugged design with customized sensor material design

- Working temperature upto 400⁰C & 16barg or higher can be achieved

- Better accuracy < ±2%RD of mass flow rate

- Highest turn down ratio 100:1 or better, too sensitive throughout flow ranges.

- No pressure drop saves energy (pressure) loss

- Versatile & Cleanable sensors (auto-purging) design

- Can be used with too low upstream straight length with special installation procedure

- Low cost of ownership against other flow technology

Conclusion

Cement plant mainly consists of large duct with blowers (FD & ID Fan) where conventional flow measurement is done with Differential pressure sensor as primary elements such as Averaging Pitot tube, Orifice, Aerofoil etc. which are prone to clogg, insensitive to changes in flow velocity, and considerable pressure drop occurs with lower accuracy is now proved to be overall uneconomical to be used against Insertion Thermal Mass flow ( Heat dissipation technique) metering the latest development after long proven track record.

Now further development on material compatibility with hot gas having heavy dust concentration and high abrasion are in progress which will satisfy most application demands in cement plants with few limitations of temperature upto 500⁰C. Still above 500⁰C operating temperature conventional technologies still rule the market. Hope this will help cement plant process operators to get benefit by implementing new technology against conventional flow measurement and acknowledge the benefits offered.

Author

Mr.Manish S Patel, A Chartered Mechanical Engineer with more than 24 years rich experience in process industries especially in flow measurement with a wide range of applications.

Request to kindly write us your queries related to the flow measurement applications would be happy to assist at our best. For more information contact us.