Problem

In Coffee production process, Roasting is the most critical process on coffee beans. Where heat is transferred by air flow rate on coffee beans is crucial by which taste, aroma & color are developed by air through roast. It removes chaff & small particles from the beans during roasting. Air flow is a key role in controlling a roast. Too low airflow leads to Blowers high energy consumption & low quality of roasting with high impurities, Whereas high airflow potential leads to tipping, where the edges of the beans become scorched. Due to the intense heat, the outside of the bean burns before the inside has an opportunity to develop.

Solution

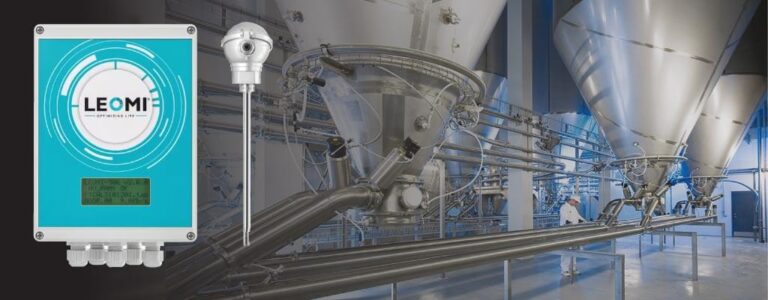

Leomi – 586 Insertion Thermal Mass flowmeter

- High turndown down ratio of 100:1 instead of DP type ( 4:1)

- No pressure drop, Works well even in high temperature & low velocity

- High accuracy upto (±2%) against available DP flowmeter (±4% FSD)

- Doesn’t require shutdown for installation & Adjustable

- No clogging due to air laden dust

- No maintenance than the existing flow meter used.

Application

Hot Air Flow Measurement for Optimizing Coffee Bean Roasting in Food Industries, India

Customer

Reputed Coffee Production Unit, India

Product

LEOMI- 586, Insertion Thermal Mass Flowmeter

Why Leomi?

- An ISO 9001:2015 company, Startup India recognized

- German technical collaboration Engineered in India

- India’s First In-house fully automatic wind tunnel calibration system

- Product quality proven for more than 20 years installed worldwide.

Installation Facts

Leomi 586 is installed in the square (1100mm) & circular duct ( 2000mm dia) of Hot air blower outlet Successfully working for since July’ 2021 with excellent repeatability.

Download the Complete Case Study