Aeration lane air controls are most imperative as lower or no air supply causes bacterial death due to starvation for oxygen & inefficient treatment whereas very high air supply increases too much bacterial growth in-turn bacteria gets hungry and dies & also increase energy cost.

Thermal mass flow meters come in handy for optimizing aeration control by measuring aeration air flow to address the need to control oxygen flow rate requirements for optimizing BOD & Energy costs in Effluent Wastewater Treatment Plant.

LEOMI thermal dispersion technology is the supported innovation for measuring aeration air flow at plants where wastewater is dealt with Largescale Municipal Sewage Treatment, Common Effluent Treatment Plants (CETP), small industrial effluent treatment.

Insertion thermal mass flow meter is a reliable technology for gas flow measurement and requires virtually NO maintenance. They are simpler to install and save blower/compressor energy costs. The meter provides direct mass flow rate measurement with the highest turndown ratio, No pressure drop, accuracy, and repeatability work well for this application against DP Types flow sensors such as Averaging Pitot tube or Orifice.

THERMAL MASS FLOW MEASUREMENT PROVIDES SOME IMPORTANT BENEFITS AS BELOW

- Optimize Oxygen demand in the aeration lane helps optimum bacterial growth

- Saves Energy cost by approx. 5%-15% depending on plant operation conditions.

- Directly control dissolved oxygen for better process control

THERMAL MASS FLOW METER APPLICATIONS

- Municipal Sewage Treatment Plants

- Common Effluent treatments Plants ( CETP )

- Effluent Treatment plants for Food & Pharmaceuticals

- Aeration Blower Or compressor manufacturers

INSERTION THERMAL MASS FLOWMETER AN IDEAL FOR AERATION AIR FLOW CONTROL

NO PRESSURE DROP

- ~3-10 mmwc across operating ranges

- whereas DP Type may have 50 mmwc -1000mmwc in aeration blower

- Approx. 8 – 15 % power saving typically against DP Type

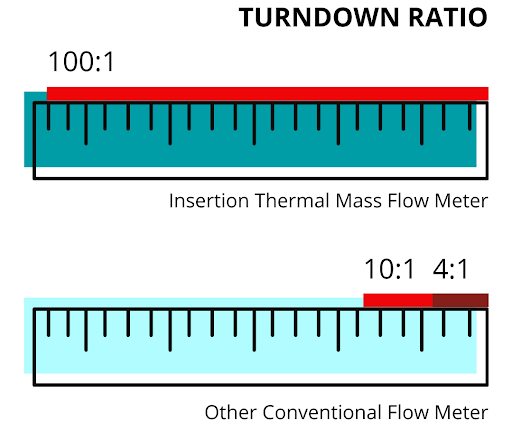

HIGHEST TURN-DOWN RATIO

- Typically 100 : 1 Turn-down ratio proves to be most sensitive.

- Whereas Pitot or Orifice DP Type 4:1

- High measurement sensitive high signal resolution for fine analysis than Orifice, Aerofoil, Pitot Tube.

MAIN BENEFITS OF LEOMI'S INSERTION THERMAL MASS FLOW METER AGAINST OTHER FLOW TECHNOLOGIES

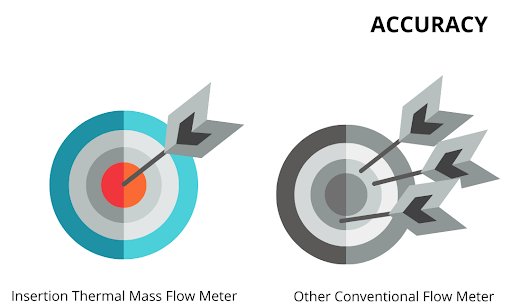

HIGHEST ACCURACY

- Direct Mass Flow Measurement whereas DP are Volumetric

- >±2.0% of reading better

LOW TOTEX ( TOTAL EXPENDITURE = CAPITAL + RECURRING ) COST

- Installation needs <2 hours with planned shutdown whereas DP needs higher time around a day & higher installation cost.

- Virtually NO Maintenance as work same as Pt-100 Temperature Sensor

- NO Shutdown required for preventive maintenance whereas Other Vortex needs shutdown.

ADJUSTABLE DESIGN

- Insertion Type is adjustable & with programmable pipe diameters whereas Inline type are for specified pipe size.

- Programmable gas other than air is possible

CLEANABLE SENSORS

- Can be cleaned by compressed air or by recommended liquid solutions after removal from measuring stream for routine maintenance & provides repeatable reading all the time.

- Whereas DP Type ports get clogging.

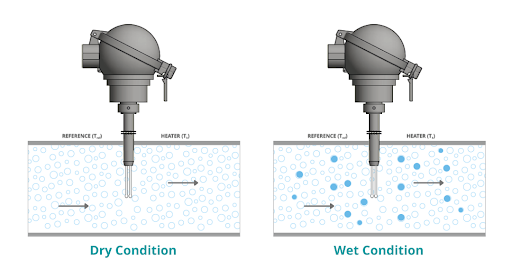

Works excellent in Dry and Wet Aeration Air