Wastewater treatment plant automation is getting crucial day by day due to complex processes & un-even wastewater quality due to modern lifestyles having a wide variety of contaminants. There are many important parameters to be monitored to optimize the purification process. Wastewater treatment mainly depends on the loads of wastewater and aeration process. Various flow measurement techniques are now emerging with respect to fluid & process conditions.

Where is Wastewater Treatment required?

The wastewater treatment process needs accurate, reliable flow measurements for defining treatment conditions. Major areas where Flow measurement in wastewater treatment is required are :

- Influent wastewater (Raw wastewater) from drainage or city sewage

- Primary treated wastewater

- Secondary treated wastewater

- Aeration air in aeration lane for optimizing Dissolved oxygen (DO)

- Chlorine dosing precise monitoring

- Precise corrosion inhibitor dosing

Flow measurement technology

Flow measurement technologies involved in wastewater treatment plant processes are as below

- Electromagnetic Flowmeter (Full Bore Or Insertion Type)

- Non-Contact Ultrasonic Flowmeter

- Insertion Thermal Mass Flowmeter

- Open Channel Ultrasonic Flow meter

- Coriolis Flowmeter

- Orifice Flowmeter

Above are major flow measurement technologies used for monitoring & controlling wastewater treatment processes.

Let’s describe in detail each flow measurement technique above with its advantages and limitations related to its application.

1. Full Bore Type Electromagnetic Flow Meter

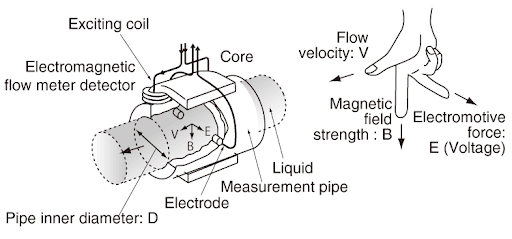

Electromagnetic flow meters work by using Faraday’s Law of induction. Inside an electromagnetic flow meter, there is an electromagnetic coil that generates a magnetic field, and electrodes that capture electromotive force(voltage). Due to this, although it may appear as if there is nothing inside the flow pipe of an electromagnetic flow meter, flow can be measured.

Under Faraday’s law of induction, moving conductive liquids inside of a magnetic field generates an electromotive force (voltage) in which the pipe inner diameter, magnetic field strength, and average flow velocity are all proportional. In other words, the flow velocity of liquid moving in a magnetic field is converted into electricity. (E is proportional to V × B × D)

As the flow changes, the electromotive force (voltage) captured by the electrodes changes as follows.

Advantages

- Is True Volumetric Liquid flow measurement independent of temperature, pressure, density, viscosity & velocity profile

- Improves reliability with No moving parts with negligible pressure drop

- Works well even in solid slurries with air bubbles with a noise suppression circuit

- Excellent for flow measurement of Sewage water & slurries, Raw Water, Effluent water, etc.

Limitations

- Unable to detect liquids with low electrical conductivity (<1?siemens/cm) such as Hydrocarbons & Solvent etc.

- For large pipe diameters, it is more costly than the Ultrasonic flowmeter

- Contact type flow technology has to wear & fouling of liners and electrodes.

2. Insertion Electromagnetic Flowmeter

Insertion Electromagnetic flowmeters are an economic alternative to full bore flowmeters. They consist of an electromagnetic coil mounted on the end of the sensing probe. It is an alternative for economical installation for large pipes in existing water distribution systems where provision for flow metering was not originally made. The assembly can be installed in existing pipelines without the need for major excavations or alterations to pipe work normally associated with the installation of full electromagnetic flowmeters.

Advantages

- Works well for Water distribution piping,

- Excellent and economical for large pipe diameters from 200mm to 2000mm

- Low cost of installation and easy sensor isolation.

Limitations

- Lower accuracy (2%) than full bore electromagnetic flowmeters

- Not suitable for pipe diameter less than 200mm

- Not suitable for liquids with high solid impurities

Above are some highlights on one of the flow measurement technologies widely used in Water & Wastewater industries in helping in monitoring and controlling wastewater, raw water etc. Will come back with another important flow technology in an upcoming article.

Conclusion

Electromagnetic flow meter is proven flow technology for liquid flow measurement with long term reliability and accuracy. There are other alternatives emerging to compete with where existing technology has limitations in performance and initial cost is a concern.

If you want to learn more about this subject please contact us at [email protected]