Gas mass flow measurement is always a challenge in process conditions. There are very few flow technologies available for achieving it such as Coriolis, Calorimetric ( Thermal Mass) etc..Gas volume varies with respect to temperature and pressure as per Charles & Boyle’s law but Gas mass remains constant. This is the main reason to measure actual mass flow rate is important to monitor in processes.

Let’s understand the difference between Standard & Actual Flow Rate first.

Standard Flow Rates

Standard flow rate is a flow rate of gas at specific pressure and temperature conditions. It is dependent on pressure and temperature conditions. It is termed as Standard volumetric

(Sm3/hr or SCFM) or Standard Mass flow rate (Kg/hr at specific standard conditions).

There are different standards conditions used internationally such as :

- ISO2533 (1.01325bara @ 15°C );

- DIN 1343 ( 1.01325bar @ 0°C);

- Standard (1.01325bar @ 20°C) etc.

(above with 0% relative humidity conditions generally or sometime varying conditions )

Actual Flow Rates

Actual Flow rate is a flow rate of gas at different pressure and temperature conditions, It is independent of pressure and temperature conditions. It is termed as Actual Volumetric ( Am3/hr or ACFM ) or Actual Mass Flow Rate (Kg/hr at actual process conditions)

Importance of Actual Mass flow rate measurement

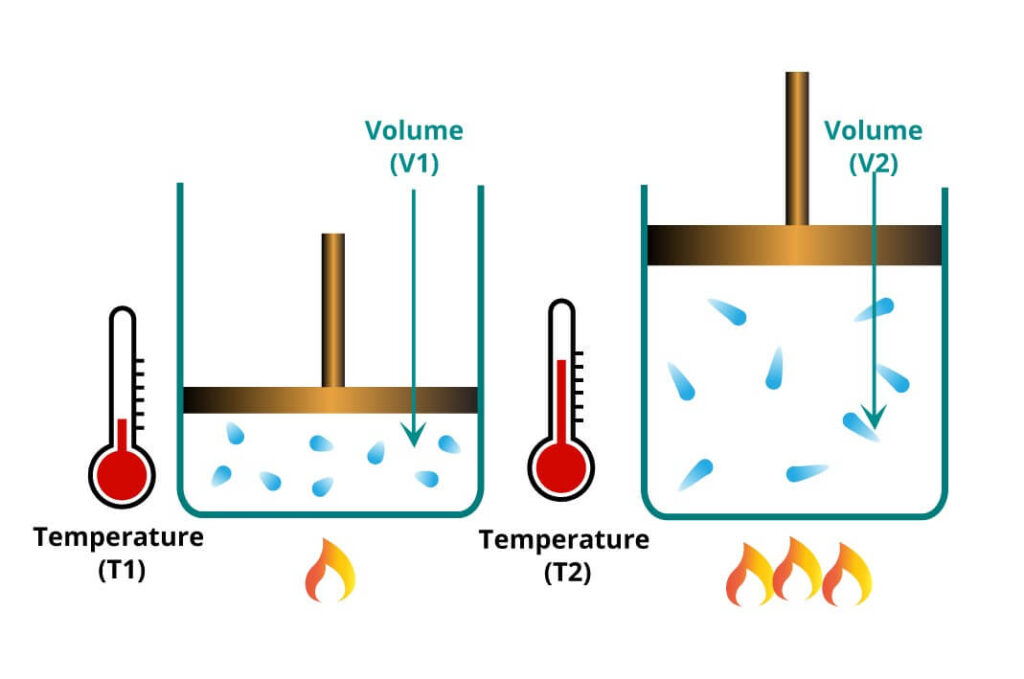

As per Charles Law states that at constant pressure ideal gas volume increases with increase in temperature or gasses expands when heated.

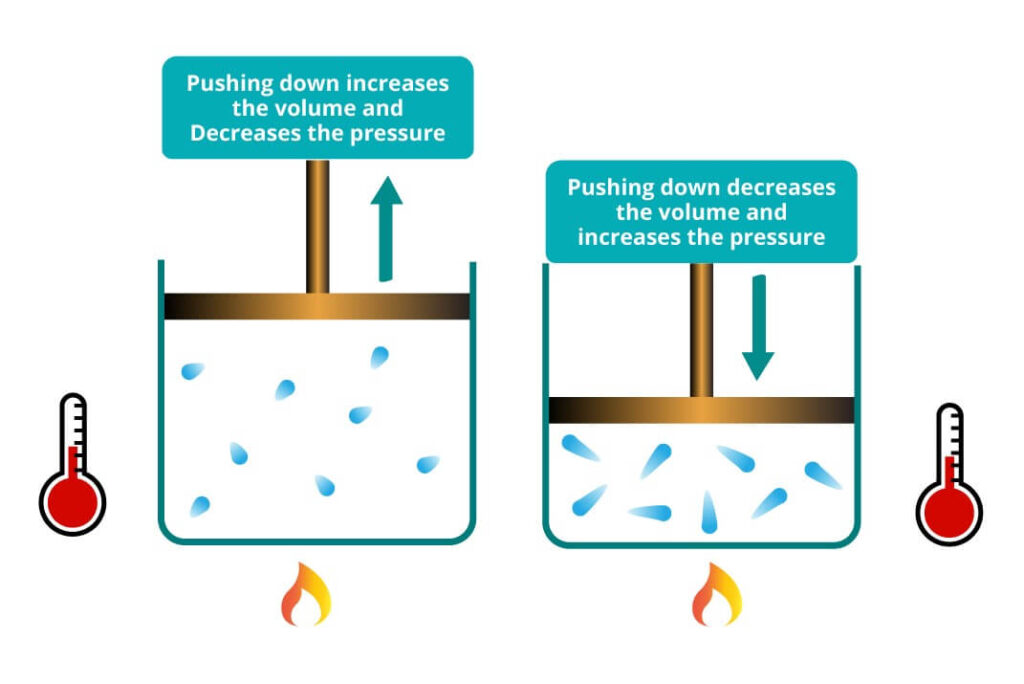

And Bolye’s Law states that at a constant temperature ideal gas volume is inversely proportional to pressure applied on the gas. It implies at constant temperature volume increases when pressure decreases and gas volume decreases when pressure increases.

From above laws we understand that measuring volumetric gas flow rate gives a huge measurement error due to the fact that gas volume varies with changing temperature & pressure conditions.

Therefore, we must measure the actual mass flow rate of gas for an accurate measurement for controlling the process conditions.

Leomi 587 Insertion Thermal Mass Flow Meter for Actual Mass / Volume Flow Rate measurement is developed considering the process industry’s real requirement for optimizing process conditions with accurate and real measurement.