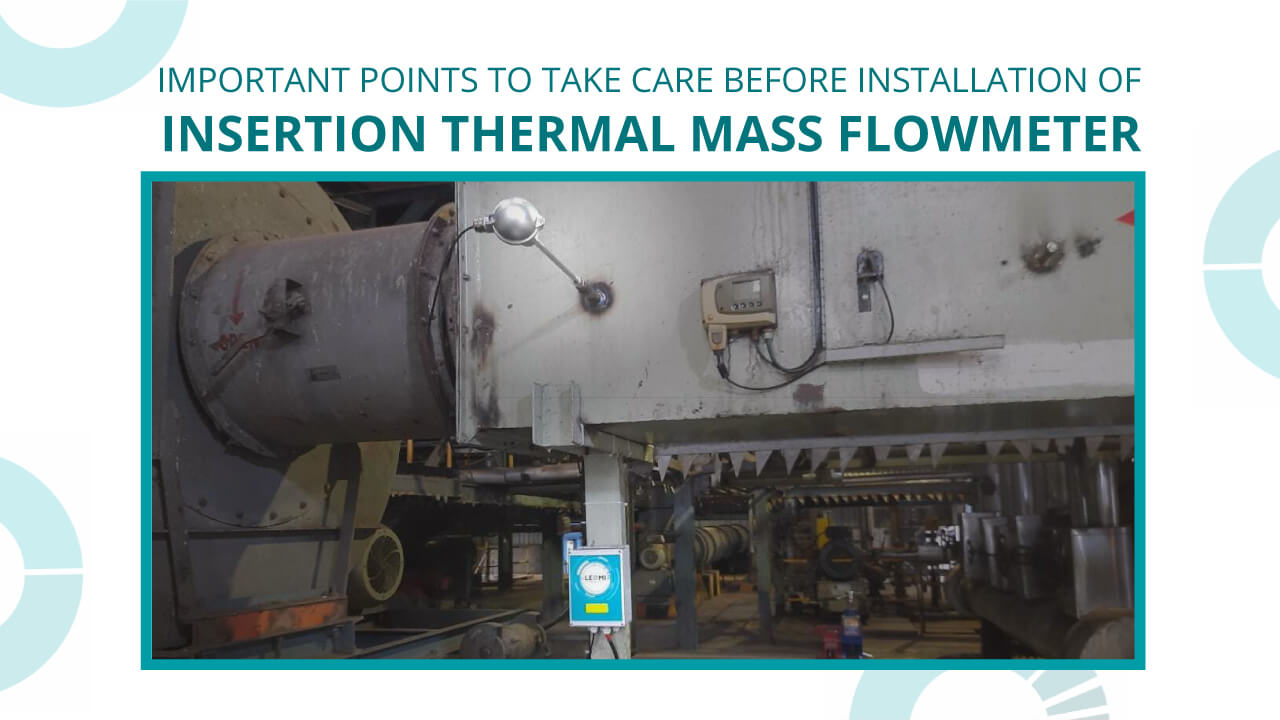

Application Study

To conduct a site survey for understanding what is the purpose of gas flow measurement based on process conditions. E.g. Flue Gas stack flow measurement in Coal based Thermal Power plant.

Insertion Thermal Mass Flow Meter Process Conditions

Confirm fluid properties as below for optimum selection :

- Standard Gas or gas mixture (total % proportion)

Is it a real gas such as nitrogen or a gas mixture such as biogas with 75%methane + 15%CO2 + 5% Nitrogen + 3% water vapor + 2%H2S. - Specific gravity or Density or molecular weight

Standard gas such as Nitrogen has specific gravity :1.25 or density :1250 Kg/Nm3 - Flow rates (minimum, operating, maximum) based on customers process conditions. Flow rates should be at specific temperature & pressure conditions. E.g. Nm3/hr (DIN1343 – 0⁰C & 1.01325bar), Sm3/hr (Standard 20⁰C &1.01325bar OR ISO2533 15⁰C &1.01325bar ) or Actual m3/hr as per operating conditions.

- Static pressure (minimum, operating and maximum in barg or suitable units).

Static pressure of the gas flowing in the pipeline or duct. - Temperature (minimum, operating & maximum ⁰C )

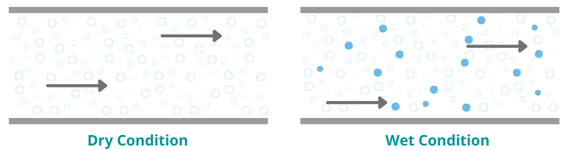

Temperature of the gas flowing in the pipeline or duct. - Gas conditions such as dry or wet gas or any details of RH% of gas flowing.

- Gas contains dust or dirt if possible dust concentration in ppm

- Gas corrosion properties or suitable material compatibility with wetted sensor part

- Hazardous or Non Hazardous. Identify whether the area of use is hazardous than protection class, zone & gas group classification is needed. ( E.g. Zone I or II Gas group IIA IIB IIC etc). For Non-hazardous Ingress protection such as IP65,IP66,IP67 needed for enclosure & sensor probe housing.

Mounting

Confirm accurately below:

- Pipe dimension: Measure Pipe OD, ID and Thickness OR confirm pipe schedule Sch40,Sch80 etc OR If available Pipe class Class A, Class B or Class C.

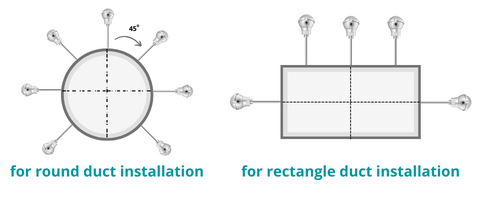

- Duct Size & Type: If Duct is in use check whether it is Square or Rectangular and measure dimensions accurately & Wall thickness

- Installation location & Mounting Type: Check plant site and identify suitable installation location having desired straight length available. If straight length not available discuss possible practical solutions.

- With or without isolation valve: If an application demands an isolated sensor probe while running, the process isolation valve needs to be installed or else not.

Orientation

Identify sensor probe mounting based on space available nearby pipe or duct.

- Horizontal

- Vertical

- Angular based on space available nearby pipe or duct.

Recommendations

Check additional points as below:

- Upstream & Downstream straight length available at mounting site.

- Power supply conditions