Modern industries have to provide an efficient and productive manufacturing operation where compressed air plays an important role as utility after water. Compressed air is an important medium for transfer of energy in many industrial processes. It has wide usage in manufacturing processes such as pneumatic conveying of bulk materials, pneumatically operated machinery such as Airjet looms, aerated bottling plant, spray paint booths, pet bottle machinery, printing machinery, CNC machines, HVAC controls etc & power tools such as valves, drills, air hammers, wrenches and many more for process automation.

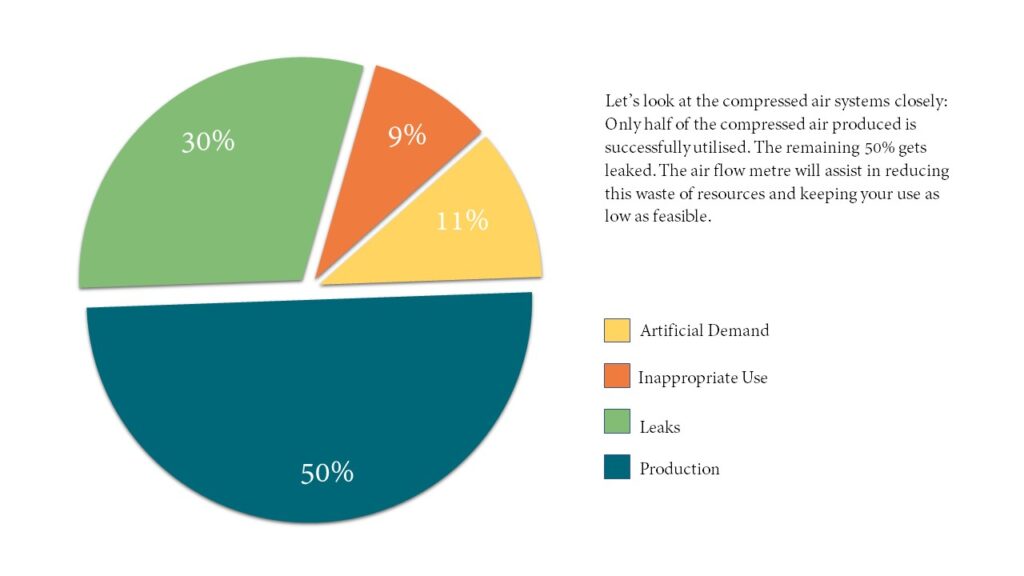

Compressed air is an invisible energy, It comprises almost 10% to 30% of energy cost in many of the process industries.

Automobiles, Textiles, Pharmaceuticals, Food and Beverages are some of the major consumers of compressed air.

Considering the above facts, An efficient selection of the right compressor type and capacity is quite important. Compressed air piping systems must be designed for best efficiency and optimization. And a plant operator must ensure elimination of leakages, misuse, overpressurization, peak load management and reduce pressure drop for efficient compressed air systems.

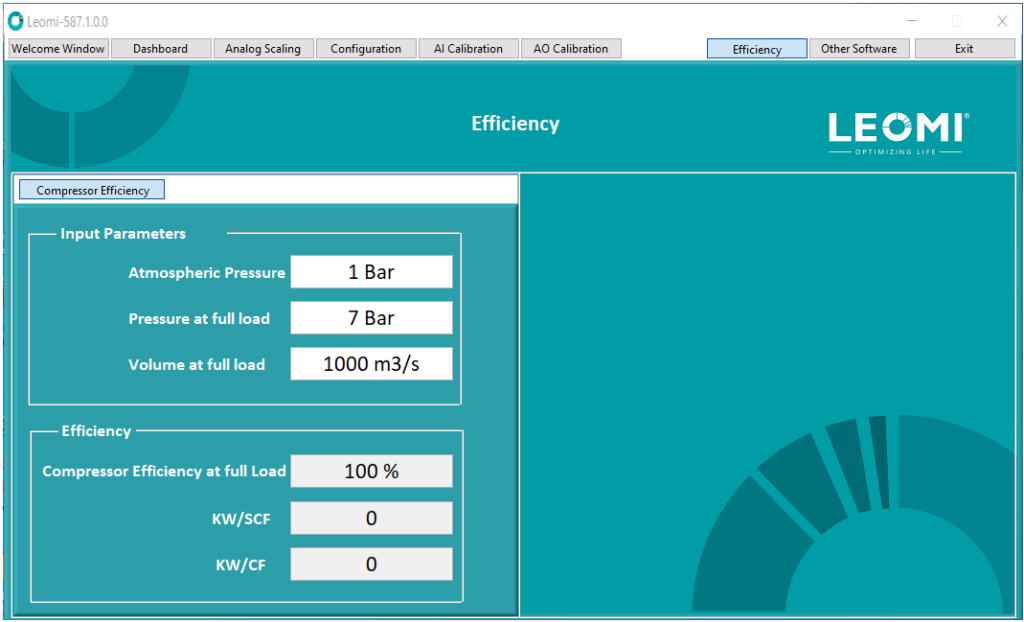

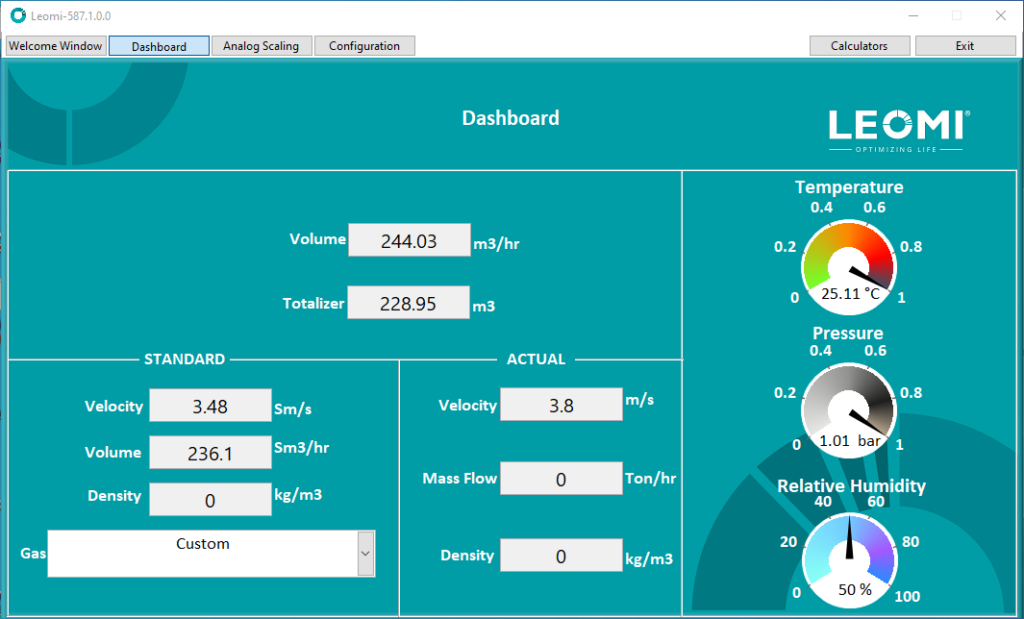

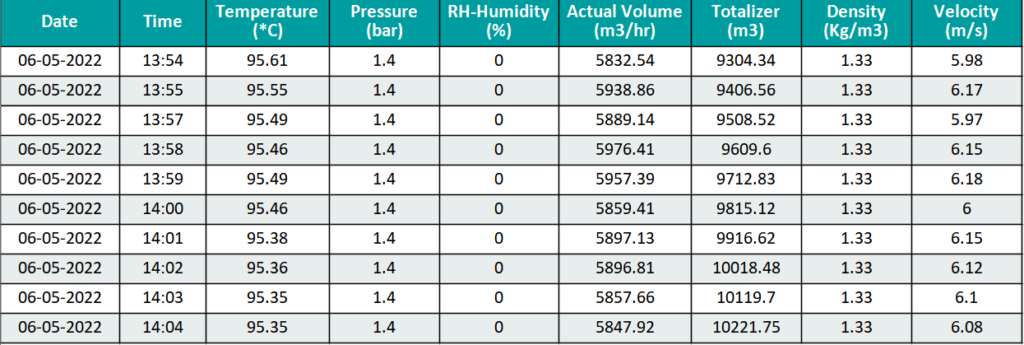

For efficient compressed air systems, Compressed air flow rate in terms of free air delivery (FAD), discharge pressure, temperature, compressor’s actual power measurement is important. In-order to achieve this goal Leomi- 587 An Insertion Thermal Mass Flowmeter is developed. A perfect tools which will measure & record with in-built USB datalogger Actual CFM ( FAD) corrected with actual relative humidity (%); Pressure, Temperature, Actual power(KW) and also calculates full load efficiency, CFM/KW with a custom built software and provides an excel report of all the parameter which makes life easier for an energy auditor.

IMPORTANT FEATURES:

- Measuring actual mass/volume flow rate

- Suitable to 15mm to 10000mm pipe sizes

- Probes with Ø=12mm/20mm(HC276) & Length up-to 2000 mm available

- Better accuracy < ±2%RD of actual mass flow rate

- Upto 4 user selectable analogue input such as pressure, temperature, power or RH% etc.

- Turndown ratio 100:1 or better

- Accurate measurement over temperature ranges upto 400°C

- In-built data storage with USB 2.0 in csv format for input parameters

- In-built auto purging system for sensor cleaning

- Ideal for customized flow control applications with PC software

Leomi 587 Software:

Click here to know more in detail about Leomi 587 Actual Mass Flow Meter.